Do you remember 3D Printing?

Do you remember the fever around 3D printing? Evangelists heralded a brave new world spearheaded by 3D printing technology. Makers, hobbyists, and strangled researchers took on to the innovation and started hacking it to suit their needs.

Everyone deemed the technology as disruptive. However, we rarely hear about it anymore. Has it disappeared? Do manufacturers use it? Was it a fad or the real deal?

3D printing technology is the perfect poster boy for disruption. Much praised by visionaries, much forgotten after the fact. But the technology is still around, and incumbents are already feeling its disruptive power.

It sets a great example of how to think about technology. 3D printing technology was first catered to an underserved market, hobbyists, and makers. The high-end market, equipped with power-tools, sniffed at the low quality and restrictions of the technology. Makers though, incapable of coughing 350.000 dollars for a casting machine, embraced the innovation. The hallmark of disruption is always similar. Underserved market and underperforming technology with plenty of potentials to improve.

While incumbent manufacturers discarded 3D printing as a playful tool, innovation in new materials and printing techniques was propelling the disruption.

The beginnings are always harsh, and while visionaries can imagine new scenarios, reality takes time to catch up. The first use of the technology was around rapid prototyping and consumer “toys.” Speed and quality were huge impediments.

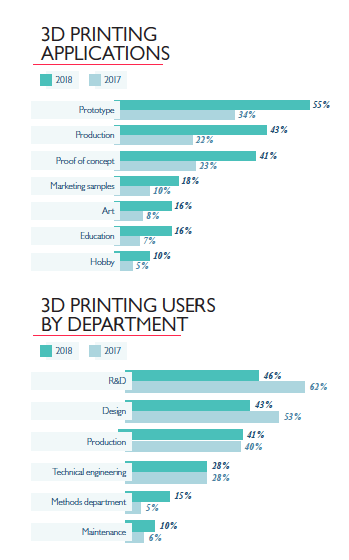

But things have changed drastically. Sculpteo’s 2018 State of 3D printing report paints a very different picture.

3D Printing in 2018

There has been a significant change in the industry, the arrival of metal. For many industries, plastics didn’t cut it. With improved technology, metal 3D printers are becoming the de facto for many companies.

The quality of the printers and the new materials are increasing, not only the amount companies are spending on 3D printing, but the range of things they’re applying it to.

One of the most significant changes is that tools produced with 3D printers aren’t just prototypes. They’re increasingly integrated into production.

The use in live production is changing the rules because it’s enabling innovation of the final product. The thing about 3D printing isn’t that they’re cheap; It’s that they can achieve the production of complex parts that are hard or even impossible to obtain with traditional manufacturing methods.

Generative design

The new technologies are giving rise to a field called generative design. According to Autodesk:

“Generative design mimics nature’s evolutionary approach to design. Designers or engineers input design goals into generative design software, along with parameters such as materials, manufacturing methods, and cost constraints. Unlike topology optimization, the software explores all the possible permutations of a solution, quickly generating design alternatives. It tests and learns from each iteration what works and what doesn’t.”

This is a blend between the fields of Biomimicry and Genetic Algorithms. Deep Learning models are capable of exploring novel and creative solutions to manufacturing problems. These algorithms have been known for a while. However, they’ve remained on a theoretical plane due to restrictions on manufacturing methods. 3D printing and new materials are changing this. We refuse to acknowledge the creativity of Artificial Intelligent systems, but we keep on using it to our benefit.

The exciting thing about this new field is its implications. We can now produce stronger, lighter and more efficient parts. Here is the catch though. Very few incumbents will be able to take advantage of this technology. Most will employ the novel approach to improve their current products. They’ll approach it as a sustained innovation.

Incumbents will have a hard time creating novel products from the ground up using these innovations. The new entrants, 3D Printing-first companies, will be the ones to take advantage of generative design technology.

I’m very intrigued to see what they come up with. In contrast to incumbents, startups will use these innovations to deliver radically new products to the market.

Industries benefiting from 3D printing disruption

Which industries are benefiting the most from this? There are three big groups, but they won’t be the only ones.

Aerospace industry

The arrival of metal and ceramic 3D printers is transforming the aerospace industry. From lighter designs which save fuel and increase range, to cheaper production of critical components.

One of the most captivating uses of 3D printing has been SpaceX’s new rocket booster design. Not only it has cut production time, but it has allowed new functionalities impossible before at a fragment of the usual cost.

The speed and cost reduction of satellite parts is one of the driving forces behind the Low Orbit Micro-satellite constellation revolution. Production of micro-satellites at scale will enable us to create a genuine global communication’s system. Those that control the communication channels influence the world.

Health & Medical industry

Another obvious winner is the medical field. The development of several bio-inks is bringing incredible developments. I would argue that when it comes to biological applications, we’re still in a very early stage.

There are impressive advances, ranging from biological scaffolding for organ growth to full steam-cells printed corneas. Eventually, the field will allow for ad hoc organ printing but still requires more time to mature.

Nonetheless, some applications, like bacteria-based ink tattoos are jumping to the consumer side. Organic ink will allow us to print logic gates on our bodies. These tattoos act as live, real-time detectors of diseases, chemical changes or health problems.

Another application that might have far-reaching consequences is the printing of tissue to experiment drugs on. Regulatory approval for drugs is a lengthy process. The printing of target tissue or a part of an organ will serve as a much more realistic testing ground for specific compounds. This still ignores interactions with other cells or chemicals but will be a big step towards a much more robust testing ground.

Automotive industry

The closest industry to benefit from 3D printing advances is the automotive one. Not only is AI already disrupting it, but such disruption has an immediate impact on most strata of society. We live in an auto-driven society, and as such, any change in the nature and quality of transportation will have dramatic consequences.

Three trends are colliding in the industry. On one side we have the rise of the environmental conscience and the need to move away from fossil fuels. This change is being led by the electrical vehicle (EV) and is irreversible. EVs require fewer parts than their combustion counterparts. New 3D Printing companies will begin to supply next-generation parts for EVs.

On the other side, the use of Artificial Intelligence to deliver true autonomous driving capabilities requires a whole new array of sensors, parts, and unique designs. The fact that there is no driver will remove the need for steering wheels, and the cockpit will be redesigned. 3D Printing will be essential for the new redesign of the car structure.

Finally, the use of autonomous vehicles will precipitate the massive adoption of ride-sharing instead of ride owning. The trend is already there, but AI systems will accelerate the dismissal of car ownership. Shared car fleets will be standard. Fleet managers though will encounter a new problem. Cars aren’t designed to sustain such continuous use of the resource. Car parts will erode at a quick pace, and car maintenance will become a significant cost for operators. New modular car architectures that reduce the cost of support are needed. These new architectures will require novel building approaches. 3D Printing technology will deliver on this, making such companies the new players of the automotive industry.

Future trends in 3D Printing

The 3D Printing technology is on the verge of showing its true disruptive potential. It’s gone from being a hobbyist tool to becoming indispensable to keep up with the competition and the innovation theatre at large.

The next stage for the industry is the advancement of autonomous 3D Printing manufacturing. Right now, many processes require of humans. There are some experiments, though, to push the limits and achieve autonomous manufacturing capabilities.

Another big step yet to be achieved is the necessary autonomous assembly of 3D printed parts. There is an increasing number of printers that are capable of printing different materials and textures. Still, such all-in-one printers deliver subpar quality. If I had to guess, I would say that 3D System’s modular factory approach will be the future.

The combination of specific modular printers with autonomous robots will deliver on the assembly part.

The last hurdle is the increase of speed in the production of parts. Several trends are being explored here. The first one is the use of generative design mentioned before. Such models allow for fewer elements as complex topologies can substitute several assembled parts. Another one is the improvement of the extruders and techniques used to print. One of the most impressive ones is the Rapid Liquid Printing developed by MIT. It’s still very experimental, but it will allow to break the additive layering hurdle and speed up the process orders of magnitude.

Final words

As I said at the beginning of this article, 3D Printing technology is a disruptive innovation. It will, not only change manufacturing but the kind of products we can create with it. It will unlock new design capabilities that will disrupt whole industries like the automotive one.

Most incumbents are either using 3D Printing to improve their time to market or ignoring it all together. As with other disruptive technologies like Blockchain, they’re missing the point. The real revolution isn’t about making your process more efficient. It’s about enabling new business models around entirely novel products that are only doable through 3D Printing cutting edge technology.

Incumbents will be late to realize this. They’ll insist in employing their traditional business model, upfront purchase. 3D Printing technology, though, enables massive customization and the move towards a pay per use or pay per impact business models.

Are you making something physical? You should be thinking of designing the whole process for 3D Printing.

If you like this article, please share it, and invite others to follow the newsletter, it really helps us grow!